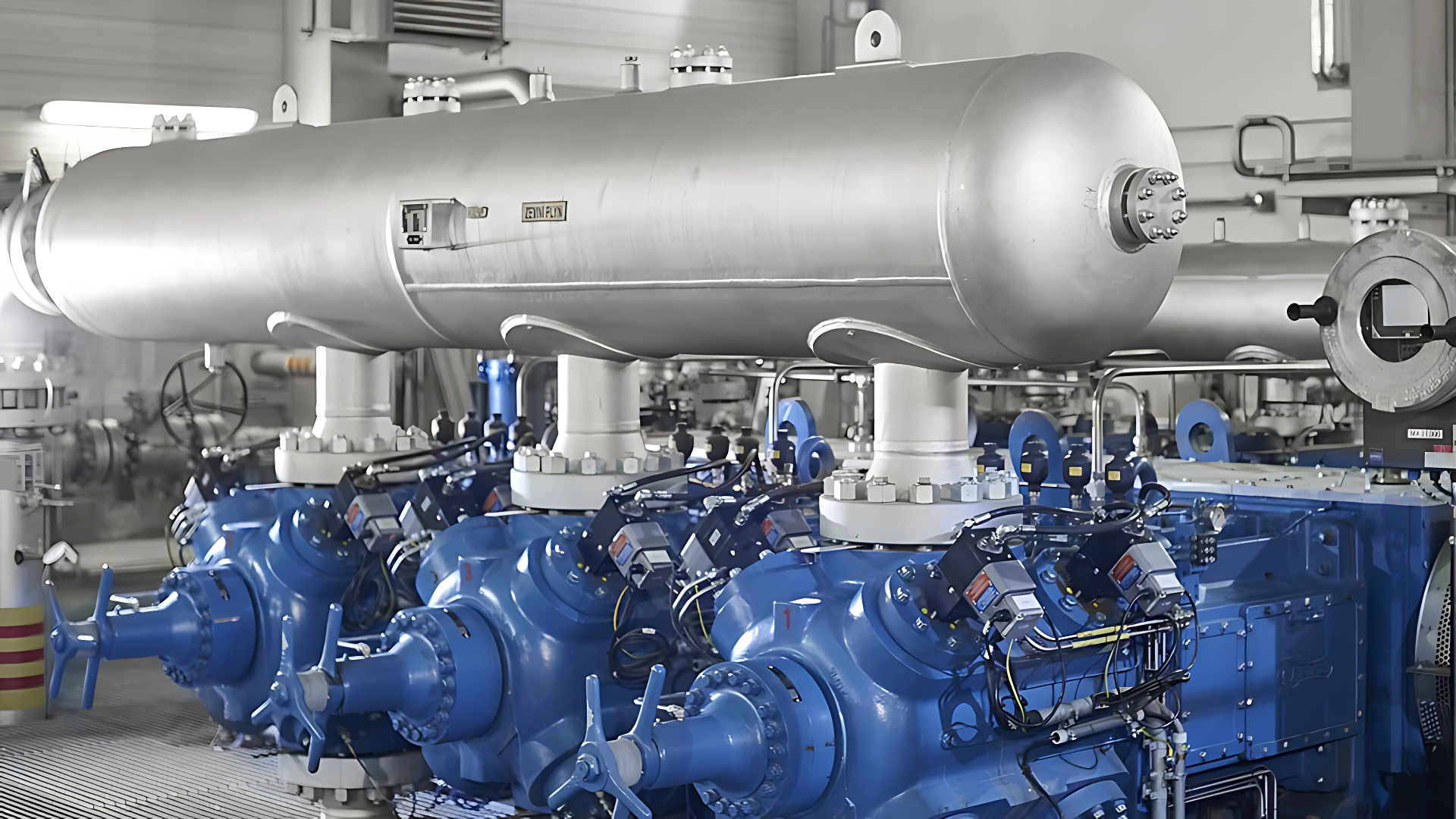

Spare parts processes at Krones – transparent, integrated, and customer-focused

As a global leader in filling and packaging technology, Krones restructured its spare parts business to sustainably improve transparency, on-time delivery, and availability. Together with proaxia, the company implemented an end-to-end SAP-based solution that fully separates the service process from the new machinery business.

The spare parts warehouse was set up as a dedicated “plant” in the SAP system — with clear responsibilities, standardized processes, and centralized monitoring. From goods receipt to shipping, all workflows are now digitally managed, automatically monitored, and fully aligned with customer satisfaction.

This not only enables Krones to increase efficiency in logistics but also provides a solid foundation for further growth in the global after-sales business.

We can plan our business precisely, deliver to customers on time, and provide reliable delivery commitments at every customer touchpoint.