Smart service. Connected.

Predictive.

Companies in mechanical and plant engineering have been undergoing profound structural change for some time. Increasingly, new business models such as “pay-per-use” or “machine-as-a-service” are being introduced and offered to customers, while the traditional sale of new machines and equipment is steadily declining.

The industry has evolved into a service-driven business: Companies now generate a significant share of their revenue from service and maintenance. For many companies, this area is also the most profitable – offering the greatest opportunities for upselling and growth.

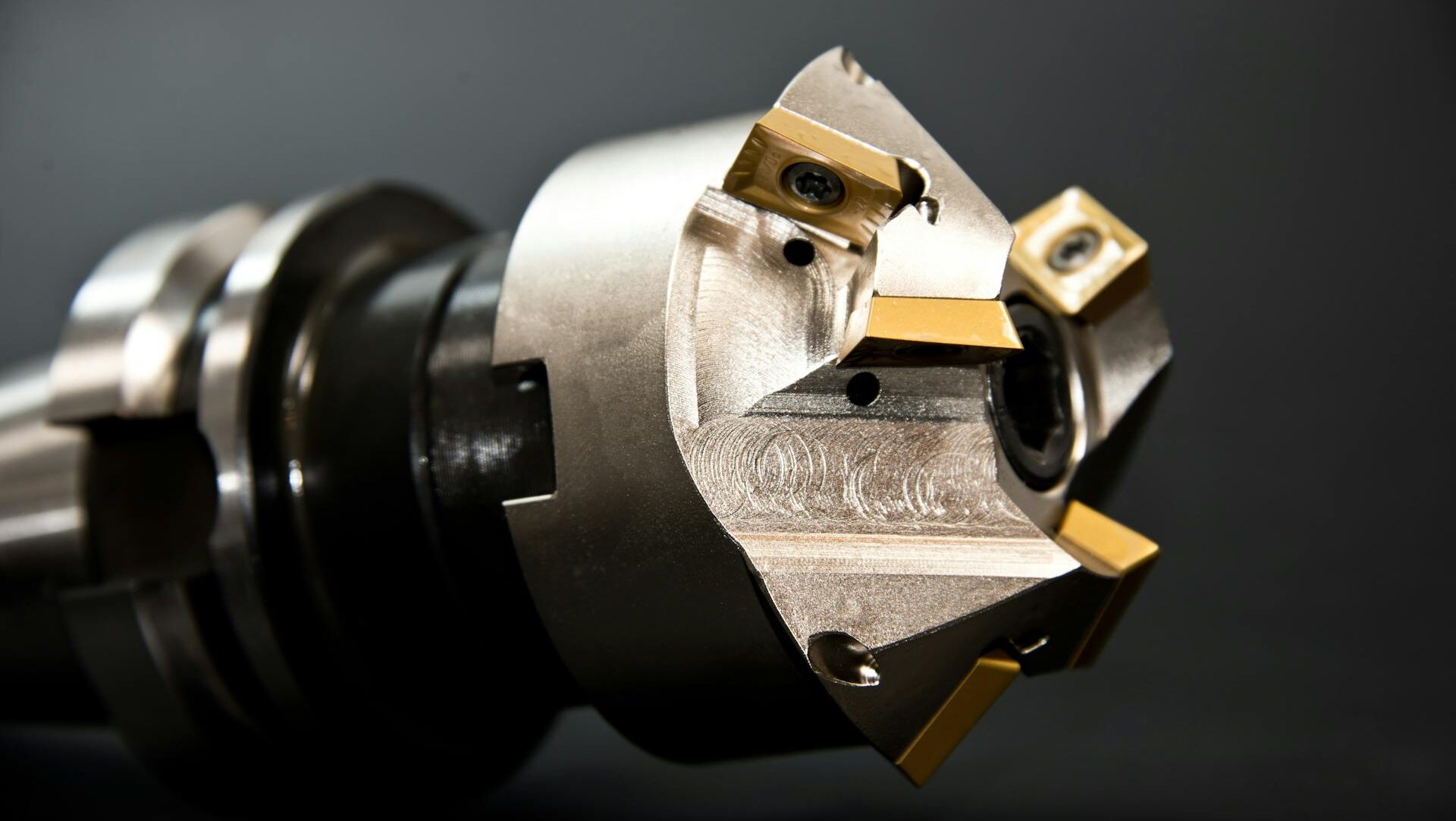

Service and maintenance are thus increasingly becoming the core business of the industry. To operate as effectively and efficiently as possible in this area, end-to-end digitalization of service processes is essential. Cutting-edge technologies such as the Internet of Things (IoT), Artificial Intelligence, and Data Analytics (Big Data) play a key role. A central element is predictive maintenance, which leverages data-driven analyses and forecasts to prevent failures at an early stage and sustainably optimize machine availability.

Downtime

Completed projects worldwide

Happy users worldwide

Let’s work together!

We create results for our customers

proaxia solutions

Service reimagined:

digital, efficient, and sustainable.

We provide the complete solution for modern service in mechanical and plant engineering: by integrating the Internet of Things (IoT), leveraging Artificial Intelligence for predictive analytics, and using cloud-based service software, we transform raw data into actionable insights. This enables automated maintenance processes, minimizes downtime, and sustainably increases machine availability.

With our solutions, your service transforms from a cost factor into a strategic revenue driver – securing long-term competitive advantages in an industry in transition.

Increased spare parts sales

Increased level of automation

Product Quality Index

Energy Generation

Value deliverd as promised